THE WRINKLES

Wrinkles as a pattern? That does not have to happen!

Annoyed by that wrinkled appearance?

Do you feel that:

“this is the state of the art and nothing can be done about it”?

Herringbone pattern

awning with overlapping seam made with 120 cm wide fabric

Honeycomb

awning with overlapping seam made with 120 cm wide fabric

Overstretched seams

awning with overlapping seam made with 120 cm wide fabric

With compression wrinkes

awning without seam made out of full fabric width

THE SOLUTION – ULTRASEAM™

An UltraSeam-Awning™, made with 120 cm wide fabric, is the solution for a wrinkle free awning. The seaming is edge to edge using a special hotmelt adhesive, the UltraSeam Tape.

IMPORTANT!

The awning fabriconly winds as well as the system allows it!

To achieve a modern quality standard, not only the fabric, but the entire awning system must be considered. The following two essential requirements make it possible…

THE REQUIREMENTS

1. factor: the seam

An awning fabric with UltraSeam™ is mandatory.

By using an ultrasonic welding/gluing machine in combination with the UltraSeam™ Tape seaming is as easy as overlap seams with conventional equipment.

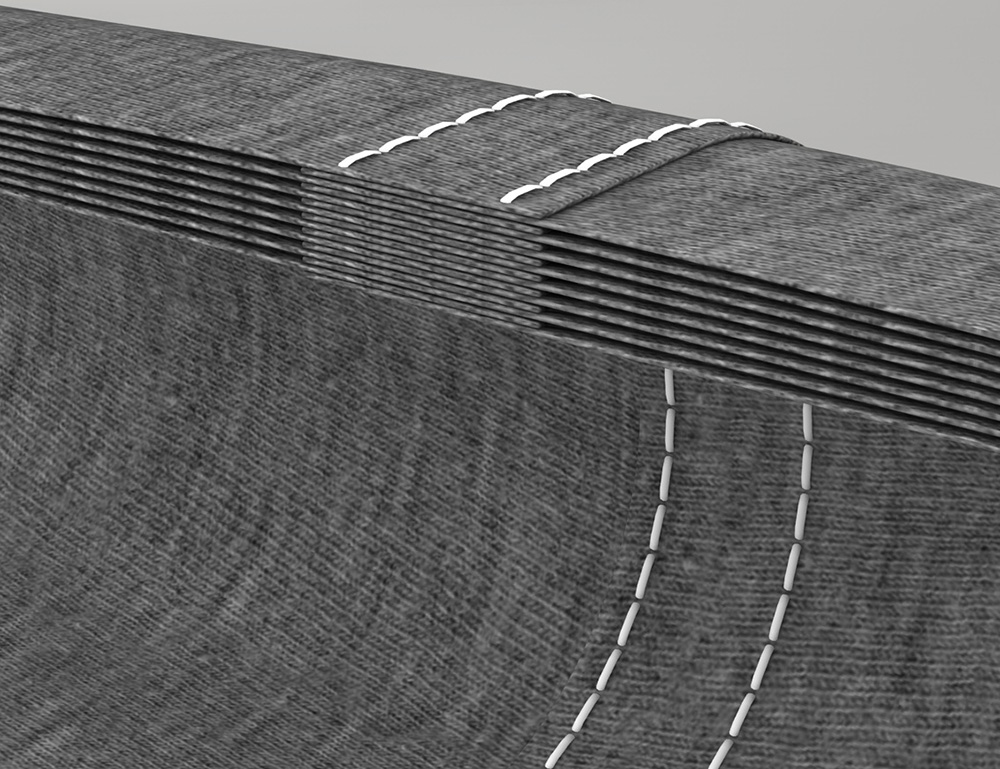

Conventional awning

UltraSeam™ awning

2. factor: the suitble awning system

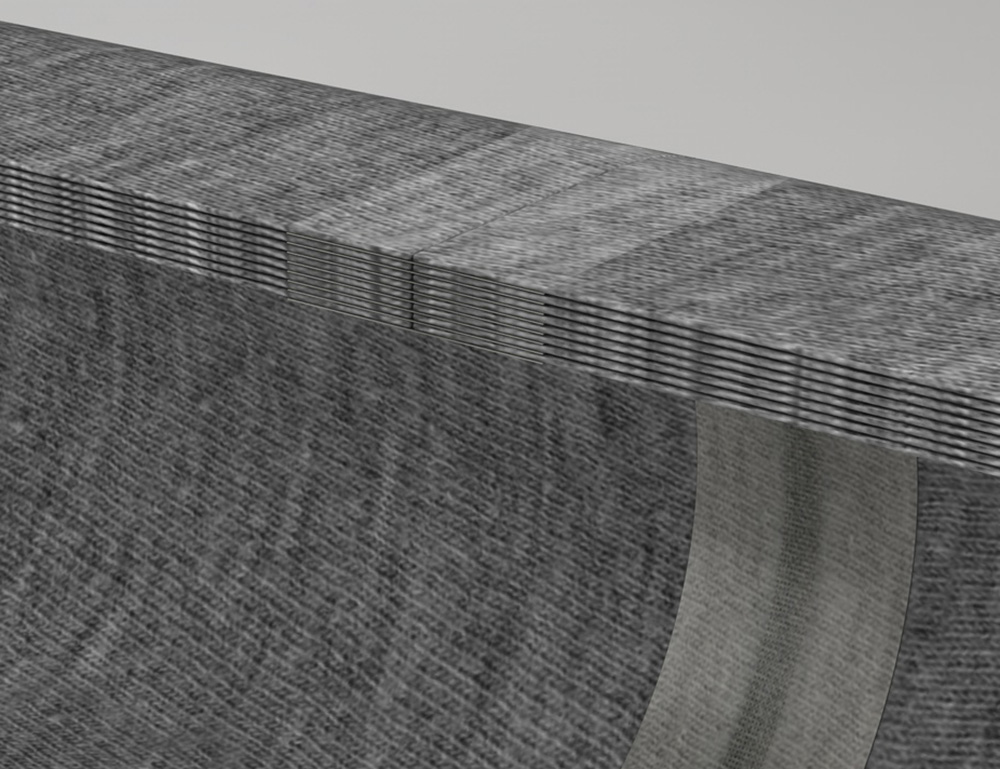

This picture of an awning made out of full width fabric (seamless) shows the effects of the fabric / system combination.

(Approx. 6.0 m wide x 3.0 m)

Conventional system

Optimized system

How could an optimized system look like?

Drawing (example): bottom view of an optimized system with UltraSeam™

(approx. 6.0 x 3.0 m)

Increased stability

By the use of an UltraSeam awning a higher stability of the system can be achieved. Because of the reduced winding diameter a bigger tube can be chosen that ensures more stability. An app. system width of 5,5 m can be achieved even without the use of a support.

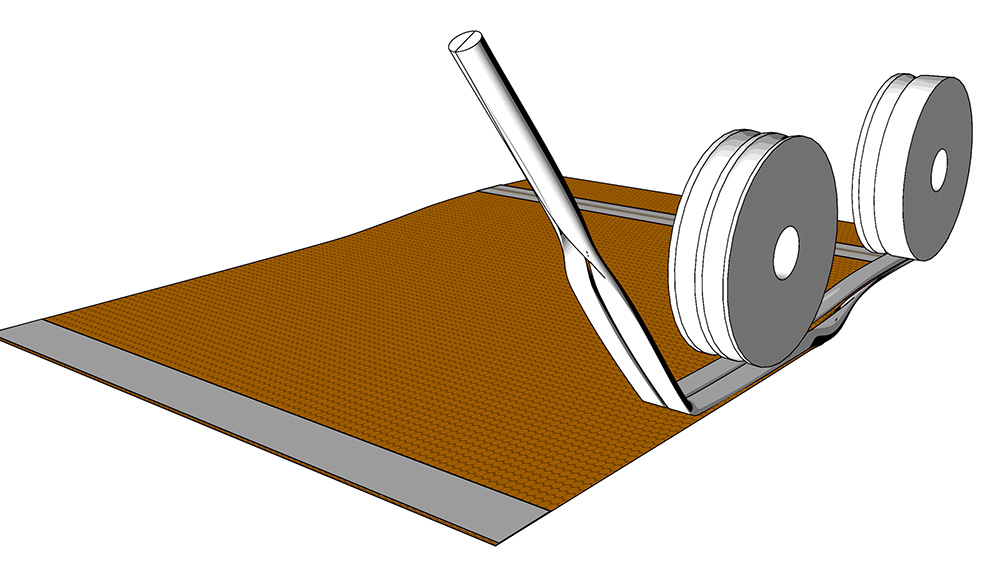

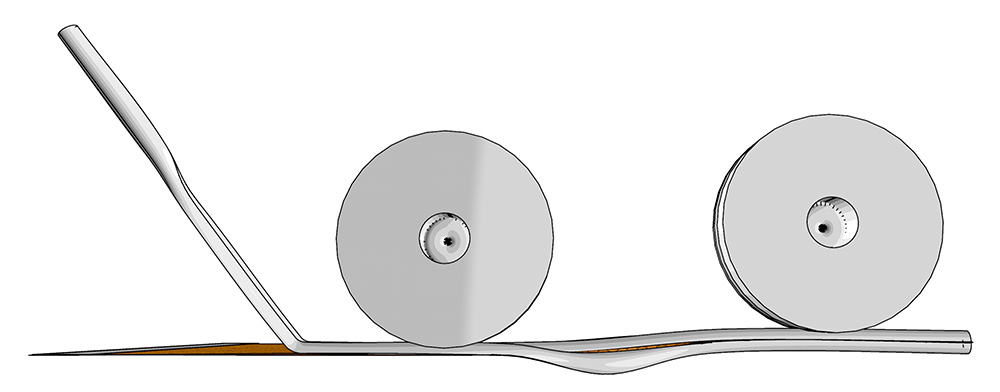

THE WINDING DIAMETER IN COMPARISON

Awnings made with UltraSeam™, have significantly smaller winding diameters!

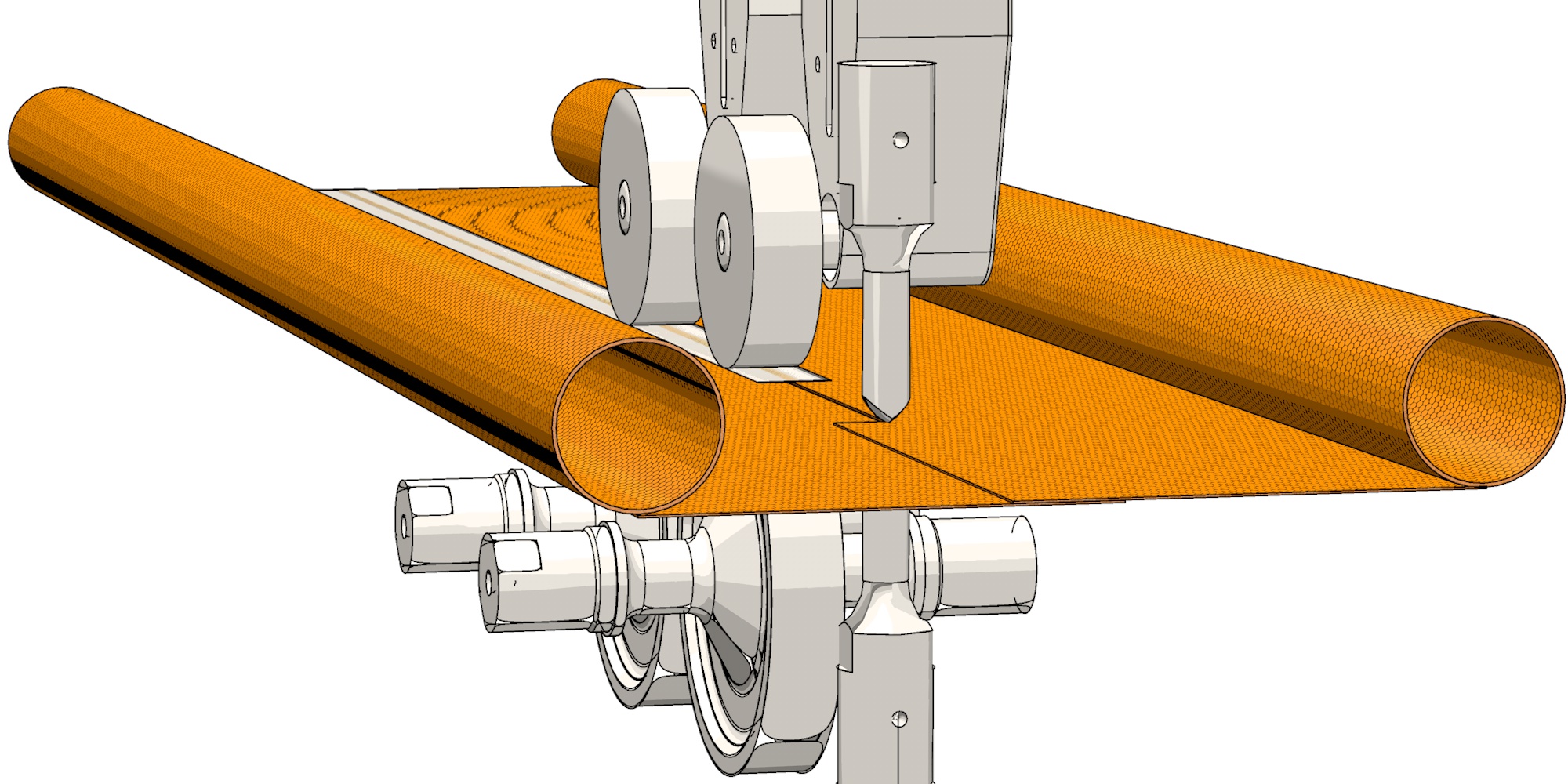

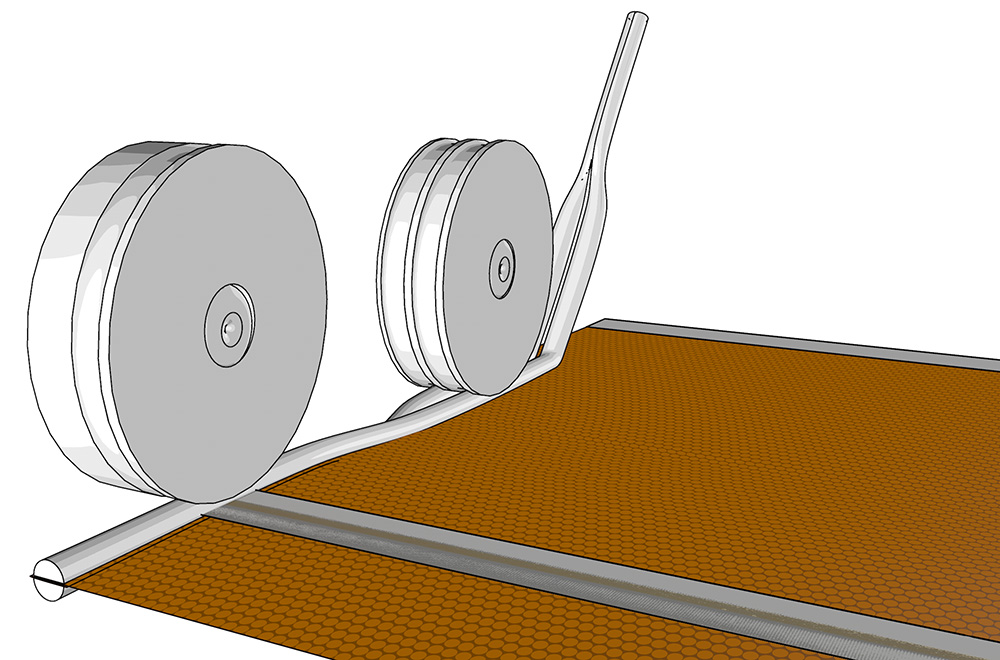

Following picture shows the concept of a folding arm awning with cassette and accompanying tube support.

A (preferably) straight tube avoids wrinkles!

Overlap

UltraSeam™

The capability:

Instead of a Ø 78 mm tube, with UltraSeam™ a Ø 92 mm tube can be used. The picture shows two common tube diameter.

Poly-acryl drop valance:

Until now it was critical to use large tube design for the drop valance to avoid wrinkles. The smaller and flatter windig characteristics of the UltraSeam™ drop valance allows use of smaller tube diameters.

Important topics for the engineering!

Due to the small winding diameter the tube supports apply lower pressure to the fabric compared to conventional designs.

Additional optimization can be achieved by combining tube supports with floating bearings.

Advantage: A bigger and more stable tube can be used in the same size of the cassette!

THE ULTRASEAM™ TAPE

Technical Specifications

UV-Resistance (top side)

With the UV resistant layer the tape can be used on the top or bottom side of the awning.

Color

The UltraSeam Tape is available in different colors, suitable for the fabric colour or as visible highlight.

[fusion_modal name=”Farbauswahl” title=”UltraSeam Colors” size=”small” background=”#ffffff” border_color=”” show_footer=”yes” class=”” id=””]

Note:

The above colors are to be regarded as basic color tones. Due to the transparency of the UltraSeam tapes and the inherent colour of the fabrics, the color tones adapt slightly to the respective fabric background.

[/fusion_modal]

Reinforcing layer

The reinforcement layer increases the pulling strength of the tape and has also a perfect balance of elasticity and resilience. Applied to the fabric it takes over additionally fabric tensions and improves the resilience of the entire awning fabric significantly.

Hotmelt adhesive (fabric side)

A specially formulated hotmelt adhesive allows this tape to be used with ultrasonic systems and typical acrylic / polyester fabrics used in the sun protection industry.

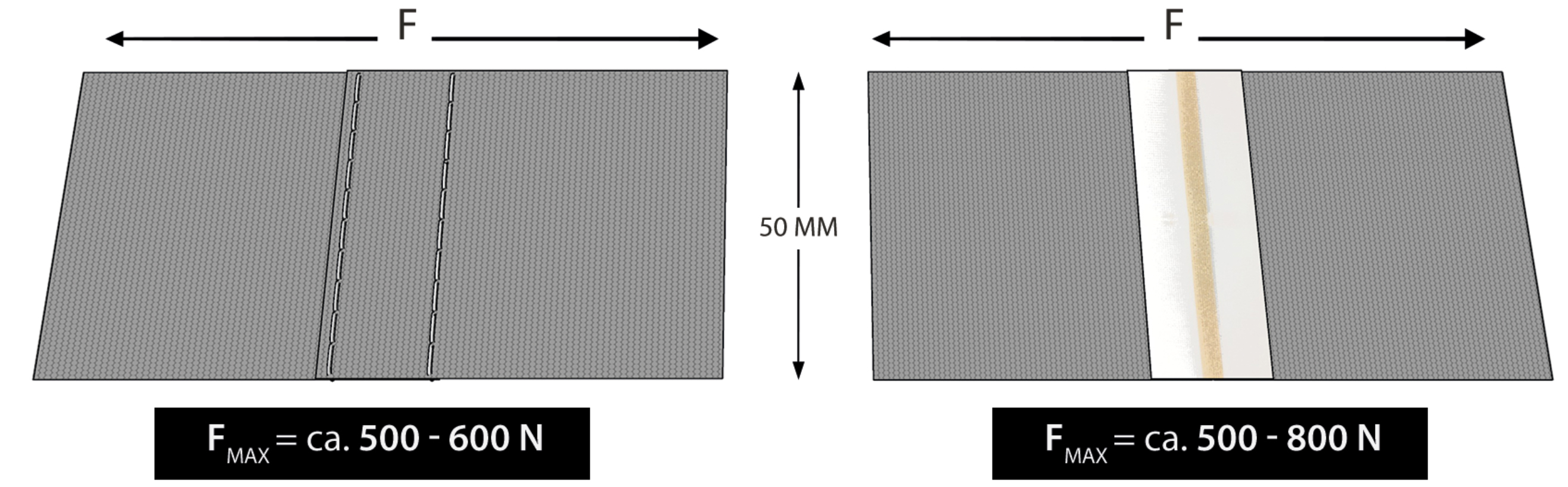

ULTRASEAM™ – PULLING STRENGTH

THE PROCESSING

The UltraSeam™ fabric is processed with an ultrasonic welding / gluing machine, the Weldsonic™ Twin of the company Jentschmann AG. Following steps are executed to achieve a perfect result:

Ultrasonic cutting and gluing

Two ultrasonic cutters that are implemented into the UltraSeam™ guide cut the upper and lower fabric during the feed. Therefore folowing aspects are ensured:

- a constant cutting edge quality

- a precise guide edge-to-edge

- no offset of the fabric design

The UltraSeam™-Tape is applied simultaneously on the top side of the fabric. The combination of pressure and ultrasonic energy activates the tape and glues it to the fabric. The seam is compressed to the fabric thickness so there is virtually no extra thickness at the seam.

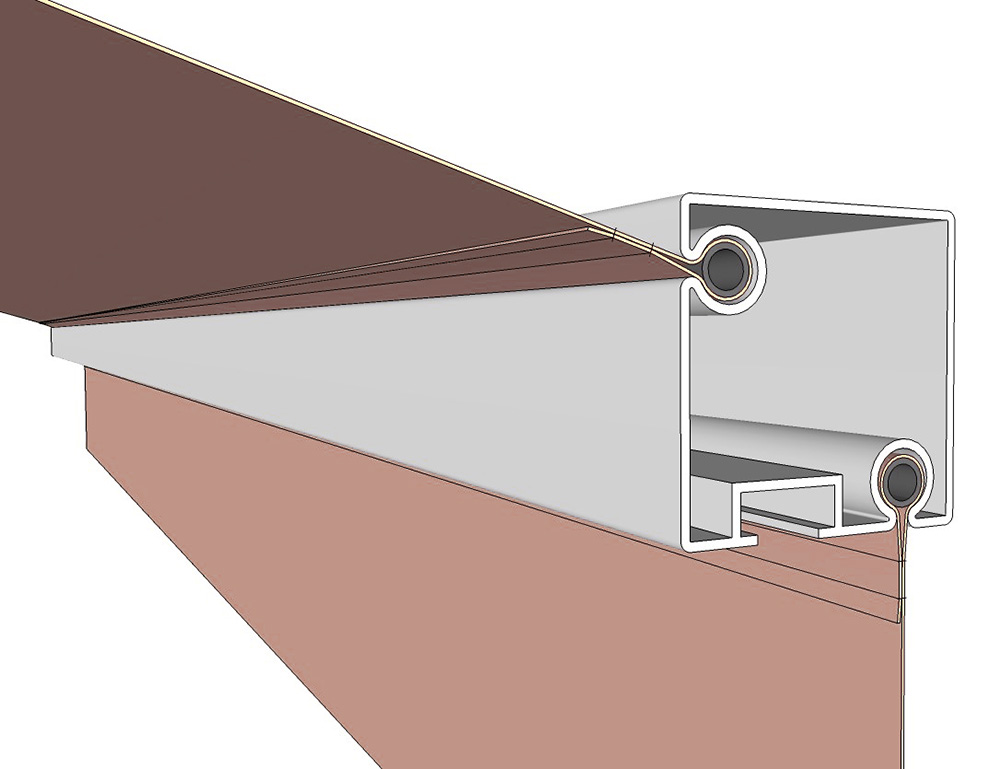

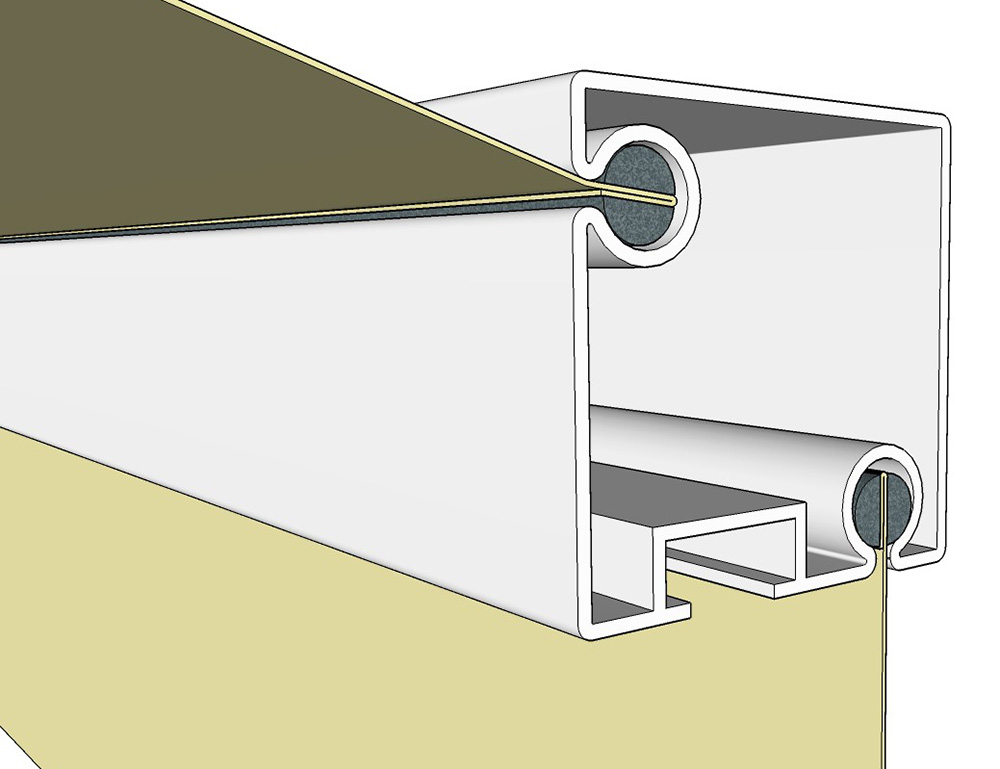

THE NEW KEDER SYSTEM

The UltraSeam™ enables a new way of PVC spline processing,

on the drop profile as well as on the tube side.

The new keder system is manufactured using a soft, solid PVC spline.

The soft spline also has the advantage of allowing some tension to be applied along the spline if desired.

Conventional keder hem

The new keder hem

The advantages

No visible seam

No stitch holes that collect dirt

Waterproof keder edge

Material savings of the conventional keder hem

THE KEDER PROCESSING

The new keder system is manufactured on an ultrasonic-welding-gluing machine, the Weldsonic™ Twin Keder from Jentschmann AG. The following processing steps are carried out for a perfect result:

A laser line allows operator to position the fabric where the keder is desired. Material will be cut and keder applied along this line, ensuring a clean, exact finish and optionally valance cut off in one step.

The machine splits the Keder, glues it to the fabric, folds, and glues the two halves back together – sandwiching the fabric between the keder.

Gluetex GmbH

Züricher Straße 17

D-79771 Klettgau Erzingen

Phone +49 7742 | 92 78 90 30

Fax +49 7742 | 92 78 90 39

info@gluetex.de

Jentschmann AG

Feldstrasse 2

CH-8194 Hüntwangen

Phone +41 44 | 735 83 83

Fax +41 44 | 735 83 84

info@jentschmann.ch

© Copyright 2019 | Gluetex GmbH | All rights reserved